Ok, After thinking about where to start for a bit it kind of makes sense to get up what i'm doing at the moment which is the tesla turbine and my theoretical improvements. First lets go through Teslas turbine :-

http://en.wikipedia.org/wiki/Tesla_turbine

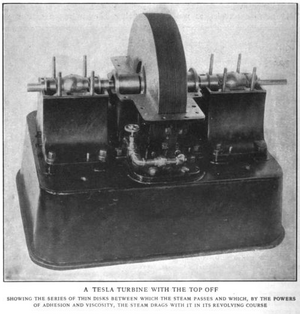

Tesla found that a gas or fluid being forced between two closely spaced flat entities exhibited an adhesive drag on those entities. He than moved forward with this to design and build his first turbine. This consisted of a set of closely spaced flat disks held together with washer spacers between plates. The center of each disk had a wide hole and a cross shaped support joining the disk to a central shaft. Pressurized gas was forced in at the space between the disks at an angle where it spiraled towards the center of the disk and allowed out through the cross shaped support. I have attached a pic of Teslas design pic.

···As a home researcher unfortunately I dont have access to some nice computational fluid dynamics packages that would be very useful here to calculate the gas flow through the turbine and hopefully see methods of improvements. The only methods available to me (and lots of other people I think) is stitting and thinking and then building it and seeing if it works. Lots of talented people have built up Tesla turbines and there are some very nice utube vids of them spooling up. It seemed a duplicated step to build one myself so after looking at many builds I sat and thought lots about it all.

···The key theory from Teslas boundary layer turbine seems to be that the gas is injected at the edge of the disks preferably using a nozzle assembly to inject it between them. Gas should then spiral in and exit the disk in the center. As the gas travels on its spiral towards the exit it exert its adhesive force onto the disks and the pull on them starts the disks spinning. My thoughts about this lead to the idea that the more uninterrupted the flow of gas from input to exit the better the transfer of power to the disks. Its known that a well designed nozzle inserting the gas between the disks works better than just inserting it across the whole outside of the disk array. This reduces external turbulence with gas flow injected where its needed.

···My potential improvement focuses on the central area of the disk where the gas exits between the disks and where in Teslas design the star shaped support is. In an ideal implementation (I think) the disks would be placed closely together with the gas injected at the edge and exit in the middle. The gas would have an uninterrupted flow through out its entire path.

···In teslas build the star shaped spacers at the centers of the disks only allow the gas to exit when it can get to one of the four sections where the star doesn't protrude from the center to the edge. In a test where the disk and therefore star was held stationary whilst the gas was injected the gas flow would stabilize to flow towards the center, bump into the protruding star supports, flow round them then exit. This would create flow eddies and areas where the because the spiral flow was not wholly spiral the power to the disks would be reduced.

···Now thinking about it as a spinning disk. If the gas injection flow is constant that central spinning star will create a slow moving obstacle at initial startup causing huge eddy flows. As the turbine spins up these eddies will change which will change the spiral gas flow and hamper power transfer. In (my) theory each size of turbine of this type would have an ideal gas flow rate where the input to the turbine matched the spinning star to the point where the gas flow was least impeded.

···So the theory is that disks with no supports in the center and spacers at the sides would work well for gas flow. Unfortunately holding the disks in this position and getting power output from them would be impossible (well for me anyway). I therefore had to think of a way of keeping the disks apart whilst holding them impeding the gas flow.

···What I came up with is the stack of disk would be held apart with spacers at their edges. The spacers will be shaped to allow gas in then 'aim' it towards the direction of flow to start the spiral. The centers of the disk would have no support between disks with the exit hole free to accept flow from all angles. The end two disks will have central pivot acting also as an exhaust for the gas. The disks will be encased in a chamber which is then pressurized. The gas gets pressured into the input holes between the disks spacers, from there directed sideways encouraging it to start its spiral flow to the center. At the end of the spiral it enters the center of the disk and heads sideways to the exhaust at the end. In my theory this will work :) I need to build one to test the idea it doesn't initially have to have a spinning output shaft, just spin the rotor which should make a build easier.

···As I dont have a nice machine shop of my own and I cannot justify spending out on getting a unit made just to test the theory I needed to make a test unit up using parts I could work with and bits I could get hold of. I settled on 8 cds for the disks as they are nice and flat, readily available and can be glued. My local plastics shop was nice enough to donate some abs plastic offcuts to the project. After looking into a few things to act as the central rotors/exhaust simple speedfit pipe and 2 pipe inserts offered the most readily available and cheapest solution available. I also bought from the plumber merchants some plastic glue of the type used to glue abs pipes together and some silicon sealant.

···Below are the dimensions for the turbine housing. The plastic was cut using a jigsaw from B+Q setup on a workbench using gclamps.

···To get the whole through the center of each end panel I marked out the center on one, clamped the two together then drilled through them both. I started with a small drill bit and expanded up to the 15mm that is the cd center size and the speedfit pipe size. After that I used the ABS pipe glue to glue together the housing sections, the two shorter end sections first followed by the longer ones. Using a bit of the speedfit pipe through the center of both end panels helped to hold the whole thing in position while the glue started to go off. In glueing it all together I only glued in one end panel allowing turbine insertion. After the glue had set overnight I glued in the corner braces which also act as spacers for the end panels. Another overnight glue set period happened.

···Next I chopped two twoish inch lengths of the speedfit pipe up and inserted a pipe insert into each. These where then inserted into the end panels with the inserts facing towards each other (to the center of the turbine housing) This was the housing nearly done, just the end panel to put into place once the turbines in and then silicone it in.

···Turbine parts where next and these where the trickyest to manufacture. Below is a diagram of the turbine spacer. I haven't taken the dimentions off it (tricky with all the curves) but basically its four of these per two disks (to act as spacers). These where cut out of more CDs using the jigsaw and lots of swearing! CDRW seem to work the best for cutting as the plastic is different than others as they dont seem to crack and shatter as much. After an age of cutting I ended up with the required 28 of these. Seven of the eight disks where now marked with a pen to provide starter marks where each of the four spacers would be glued from. The easiest way I found to do this was to mark a disk anywhere on its edge. Next use a ruler and measure 8.5cm across the disk and mark where it intersects the edge. Do this twice more and you should have four marks all 8.5cm away from each other. The spacers where then glued onto the disks and carefully compressed under a weight overnight. Next I got a cd pack case that usually holds a 100 disks and has a shaft up the center. One cd with the spacers glued to it was placed over the shaft with the spacers facing up. Glue was applied to the tops of the spacers and the next cd placed on top (again with the spacers facing up). Each cd was offset from the one below it by 90 degrees thus offsetting the inlets. After all the disks with spacers where placed the final disk was placed on the top followed by a load of weight and left overnight.

···The turbine complete I now placed it into the turbine housing placing the center of the end cd onto the speedfit pipe insert mounted in the rear panel. The front panel was fitted again lining up the center of the cd onto the pipe insert. The panel sits onto the housing corner supports which in turn sets the distance the panels are set apart. The speedfit pipes can be carefully pulled or pushed back and forth to set the inserts into the centers of the cds and increase or decrease the friction.

···An air intake is required so I thats what I need to work on next. I did think about drilling in another 15mm hole in the top of the turbine housing to accept a bit of speedfit but because of the plastic type of the pipe it wont glue with the glue Im using for the ABS. Im having a think about it hopefully something will spring to mind.

···The turbine spins freely given a twist of the housing which is promising. Soon I will need to borrow a air source such as a compressor, build up a valve and pipework to connect the two then try it. Im fully expecting this if it starts to spin to whizz round to the point where it jumps off the pipe inserts and the turbine impacts into the abs turbine housing. I fully intend to be standing far away at any point during testing this. If it does do this though I dont mind to much as it will have proved the theory. I will then look towards improving it and building another out of alloy with proper bearings and a power takeoff of some sort. Fingers crossed and I will report back.

I will get some photos of the turbine and housing sorted and get them posted over the next couple of days.